Easy-to-use automated internal channel Purge System removes the need of manual syringe cleaning

The smarter choice for pre-processing.

Key Features

Frequently Asked Questions

How can I save time, water, and cut cost with the RM-S1 Sink?

Due to the design efficiency of the RM-S1 Sink, it will save time in the re-processing of your endoscopes and reduce the water usage. All while providing a proper second stage cleaning of a scope. This will reduce labor times and material costs, ultimately saving money in a cost-effective manner and increasing productivity in a busy endoscope department.

What's the benefit of having a large sink basin?

Unlike some units the sink basin is large enough to accommodate the bending radius of flexible endoscope without putting any undue stress or strain on it. While still having ample amount of room to allow for easy manipulation of the scope ensuring that a staff member can fully brush and wipe a scope without any undue restraint or restriction.

What's the benefit of having a sink on wheels?

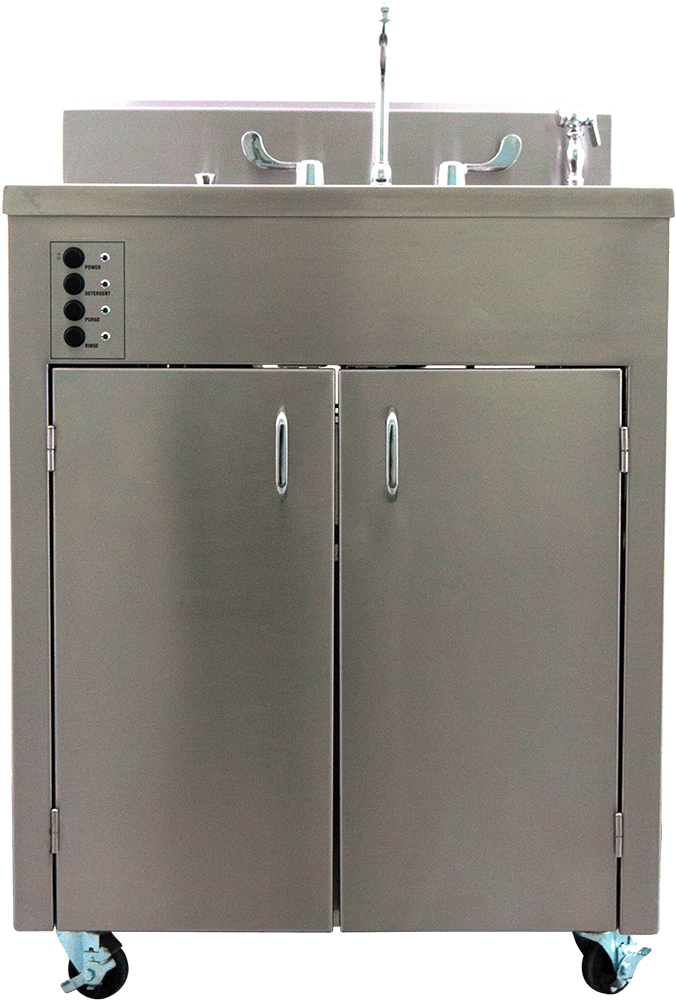

The Sink is on lockable wheels, which can be fully locked to create a fixed position or can be unlocked to allow for a unit repositioning/relocation and/or to allow for a total room cleaning.

How tall is the RM-S1 Sink?

Typical endoscope reprocessing sinks are designed with an overall height of 36 inches and a basin depth of 10 to 14 inches. This configuration places the scope at a working height of just 22 to 26 inches, which can cause leg, back, neck, and shoulder strain and discomfort during prolonged use.

The RM-S1 Sink features an ergonomic design with an elevated height of 40.5 inches and a shallower 8-inch basin, positioning the scope at a more comfortable 32.5-inch working height. This improved design reduces user strain and discomfort, helping to minimize fatigue and enhance overall productivity.

Does the RM-S1 Sink have a scope to sink attachment?

The RM-S1 Sink has 5 built-in individual channel adapter attachment points. This will allow a user to connect just about any type of flexible endoscope to the unit with using our scope adapter set.

RM-S1 Sink Specifications

51” Height x 32” Width x 26” Depth

23” Length x 16” Width x 8” Depth

7 Gallons

Up to 3 liters per minute of flow when connected to 5 scope channels

Ideal safe working range of 10 to 15 PSI with built-in safety cutoff pressure switch

100-125VAC, 10A, 50/60Hz, Single Phase, GFI receptacle

50ºF to 120ºF

30 to 60 psi

Additional Information (break up and insert elsewhere

Proper manual cleaning/pre-cleaning/reprocessing, also known as “second stage cleaning” of an endoscope, is an important critical step of the overall cleaning and disinfecting process. When utilizing the RM-S1 Sink at its fullest will ensure that the final cleaning process will be more efficient and effective.

The RM-S1 Sink has 5 built-in individual channel adapter attachment points. This will allow a user to connect just about any type of flexible endoscope to the unit with using our scope adapter set.

The Sink is on lockable wheels, which can be fully locked to create a fixed position or can be unlocked to allow for a unit repositioning/relocation and/or to allow for a total room cleaning.

Following the manuals “End of Day Procedure”, you will have properly disinfected the sinks exterior surfaces, scope adapters and the internal components. Doing this will help prevent cross contamination and ensuring that the unit is ready to go for the next day’s use. Also, for an added measure of safety this process can be done at any time following a scope that had been used on a patient with a highly compromised health issue. These issues can potentially lead to other scopes cross contamination and exposure of compromising health contaminants to staff members. By following this additional procedure will help ensure a safe working environment. And as an added note unlike most others, you will not have to replace these adapters every day or once a week because they will be disinfected at the end of every day.

Each Sink is capable of reprocessing anywhere from 28 to 32 scopes in a standard 8 hour work shift.